Preserving and improving the WtE sector competitiveness

SINTEF Energy Research leads the European WtE 2030 consortium: a 3-year research project to contribute to keeping the Waste-to-Energy (WtE) sector competitive and performant as it is at the center of a complex web of interests (the public, politics, energy, economy, environment) in the development of circular economy.

Using a local, secure supply of mainly renewable feedstock, WtE heat and power from Municipal Solid Waste (MSW) combustion is an integral part of the Norwegian (and European) energy system as it produces about half of district heating in Norway.

This sector is tightly regulated and is facing more and more stringent legislation, especially concerning environmental as well as energy performance. The EU commission had a clear message to the WtE sector at the 2016 CEWEP Congress (Confederation of European WtE Plants): Extract more energy from less waste by optimisation of energy efficiency and by harnessing existing WtE capacities in the EU.

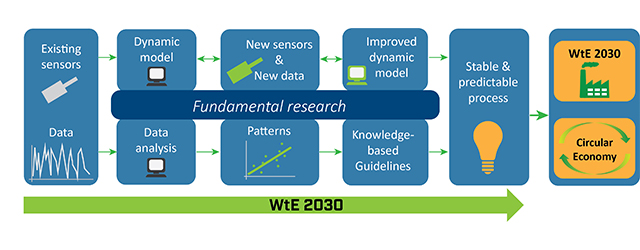

To achieve just that, we will focus on developing cost-effective solutions for a more stable and predictable process in existing installations. This is not an easy task since waste is so heterogeneous but can be achieved through modelling, a better use of the available plant data and new, better sensors.

Increased process stability will lead to increased energy efficiency, decreased emissions and consumables’ use, and increased plant capacity and availability.

Other aspects addressed in the project include WtE and the circular economy, heat storage and fly ash valorisation.

In 2019, all WtE 2030 R&D activities have made significant progress:

– SINTEF has developed a first, complete version of a dynamic model for waste incineration plants (including start-up). The model is under validation with as much operational data as possible from industry partners. The work will be summarized in 2 articles. The work will continue in 2020 by looking at possible process changes / improvements and specific operating conditions.

– Advanced analysis of existing operational data has been carried out by SINTEF in collaboration with industry partners on 2 topics: (1) prediction of waste energy content through machine learning and (2) effect of maintenance on energy production using principal component analysis. This will be summarized in 2 articles

– Concerning NTNU PostDoc study on sensor development for waste incineration: a thorough literature study was first done, followed by a detailed survey to collect insights, needs and experience from all industrial partners. The results of these two studies were combined to propose 3 alternatives for a new sensor concept to the consortium. The preferred option (based on multispectral imaging and deep learning) will be tested in 2020

– Åbo Academy has conducted a series of lab-scale multi-stage fly ash (samples from industry partners) leaching tests, including the effect of thermal treatment. The goal is to be able to extract selected metals from the fly ash. The work will be published in an article in 2020

– a European study on energy storage has been conducted in collaboration with the PREWIN Network

– a study on waste incineration in a circular economy perspective is underway

– active participation in national, European and international networks and conferences / workshops, e.g. IEA Bioenergy Task 36, ISWA Beacon, AvfallNorge, PREWIN Network

– Info dissemination (website, blog, project workshop) and education (students) are also important aspects

WtE 2030 project: vision and methodology.

R&D partners:

SINTEF Energy Research (project coordinator)

Norwegian University of Science and Technology (NTNU)

Åbo Akademi University

Funding industry partners:

Statkraft Varme

EGE Oslo

Hitachi Zosen Inova

Returkraft

NOAH

Funding public partner:

Enova

Main funding body:

Research Council of Norway (EnergiX program)

- Project type: Knowledge-building project (KPN)

- Duration: 2018-2020

- Budget: ca. 1.7 M€

Read more: